Mettocor 117

Reliable

Excellent performance

Minimal maintenance

Rugged structure for harsh conditions

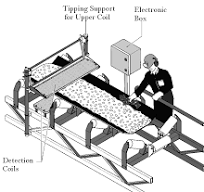

Coils

The rugged coil systems comprises of two electrically and physically identical coil sets, of which one operates as a receiver and the other as a transmitter. The coil windings are molded in a fibre glass reinforced enclosure with rubber edging.

Splice Detector (Optional)

Inhibits detection for a short period to prevent false alarms due to metal splices on the belt.

Coil Mounting Set(Optional)

A coil mounting set is optionally available for protection of upper coil against damage due to overburden on the conveyor. Materials are steel and fiberglass-reinforced plastic, impact bar cushioned with rubber.

Accurate Measurement of Magnetic Material

Instant Analysis

Reliable

Cost Effective

Applications

The Satmagan was designed especially to measure magnetite in iron ore concentrations. It can be used in various applications:

Analysis of magnetite in iron ores, concentrates and tailings.

Control of copper and nickel smelting by analyzing magnetite and other ferromagnetic oxides in slag.

Determination of martensite or ferrite in austenitic steels.

Determination retained austenite in steels.

Control of magnetizing roasting.

Control of oxidizing roasting of carbonate ores.

Controlling the heat hardening of pellets.

Control of iron ore sintering.

Materials for Analyses

Magnetite and magnetic iron can be analyzed. The sample can contain only one magnetic component, or have one component with a dominant concentration and/or specific magnetic moment.

Type of Sample

Powder, granular or solid samples maximum volume of sample 1.2 cu cm (0.073 cu inch) recommended sample size: sample container filled up grain size: An average grain size greater than 150um (100 mesh) does not disturb the measurements. For finer materials, the Satmagan gives slightly lower readings, so a different calibration curve is required.

The Range of Measurement

Fine Range: 0 to 100 % by magnetite weight .

Course Range: 0 to 200 % by magnetite weight for stronger magnetic materials.

Applications

The Satmagan was designed especially to measure magnetite in iron ore concentrations. It can be used in various applications:

Analysis of magnetite in iron ores, concentrates and tailings.

Control of copper and nickel smelting by analyzing magnetite and other ferromagnetic oxides in slag.

Determination of martensite or ferrite in austenitic steels.

Determination retained austenite in steels.

Control of magnetizing roasting.

Control of oxidizing roasting of carbonate ores.

Controlling the heat hardening of pellets.

Control of iron ore sintering.

Materials for Analyses

Magnetite and magnetic iron can be analyzed. The sample can contain only one magnetic component, or have one component with a dominant concentration and/or specific magnetic moment.

Type of Sample

Powder, granular or solid samples maximum volume of sample 1.2 cu cm (0.073 cu inch) recommended sample size: sample container filled up grain size: An average grain size greater than 150um (100 mesh) does not disturb the measurements. For finer materials, the Satmagan gives slightly lower readings, so a different calibration curve is required.

The Range of Measurement

Fine Range: 0 to 100 % by magnetite weight .

Course Range: 0 to 200 % by magnetite weight for stronger magnetic materials.

Download